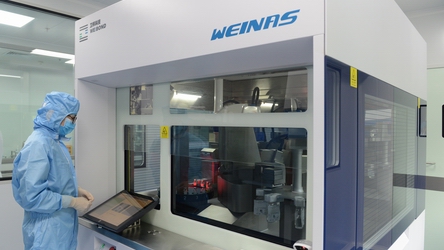

A major principle of WEINAS series is to produce safety and quality preparations in compliance with the relative pharmacy regulations.

Provides continuous ISO Class 5 sterile environment controlled by a HEPA-certified air filtration system to help contain and minimize any airborne contamination.

Utilizes image recognition and barcode scanning to verify the order and ingredients.

Records the compounding procedure via multiple cameras.

Reduces the risk of particulate contamination by using a patented liquid transfer system.

Enhances compounding accuracy through cutting-edge and patented technology.

Performs IV compounding with full-automatic, programmable, whole process and in-process quality control for individual patient-specific or batch compounding.

Utilizes gravimetric methodology, robotic vision, and advanced algorithm to provide unsurpassed accuracy for sterile compounding.

Conducts real-time monitoring and feedback control via closed-loop system to ensure superior reproducibility.

We believe that the complete isolation of operators and drug compounding process is the best protection.

Maintain continuous negative pressure inside the chamber and fully-closed environment during the entire compounding process..

Operators are completely isolated from the drug compounding process.

The waste air is 100% vented to the outside through HEPA filtration without recycled air.

Automatic medical waste disposal minimizes the medical staff’s exposure to cytotoxic drugs.

We always strive for providing our customers with a tailor-made and cost effective solution.

Patented liquid transfer system provides superior efficiency compared to syringes-based systems, with faster, smoother operation.

A single operator is able to manipulate multiple robots.

Compatible with a wide variety of containers, such as vials, IV bags, IV bottles, elastomeric pumps, and cassettes.

Supports patient-specific, batch compounding, and other compounding practices.

| Model | VD-160 | VD-160M |

|---|---|---|

| Vials Compatible | √ | √ |

| Ampoules Compatible | × | × |

| Batch Compounding | × | √ |

| Weight | 1000kg | |

| Dimensions | 1.9m(W)*1.18m(D)*2.1m(H) | |

| Area Floor Load Rating | 446kg/㎡ | |

| Electric Power | 220V±10%/5A, 1.8KVA | |

| Compressed Air | ≥0.5MPa | |

| Interface | RJ45 Ethernet port | |